Predictable uptime for laser systems in production

In a production environment, downtime is not a minor inconvenience, but a direct loss of production.

MetaQuip service and maintenance contracts are intended to to limit unexpected failures and make the availability of your laser system predictable.

You can choose to organize maintenance yourself or schedule ad-hoc service.

However, with a service or maintenance contract you structurally guarantee:

- faster support

- periodic preventive maintenance

- lower costs when replacing parts

- clarity about response times

In environments where continuity is important, a contract quickly pays for itself in practice.

Our standard contracts

MetaQuip offers two basic forms, with the option of customization depending on your usage intensity and the criticality of the machine in your process.

Maintenance contract

Suitable for environments where the machine is important, but does not cause immediate production stops.

- Support within 24 hours (email/telephone)

- Annual preventive maintenance

- Discount on parts

Service contract

For production environments where downtime has a direct impact on planning and output.

- Support within 24 hours (email/telephone)

- Annual preventive maintenance

- Discount on parts

- On-site service within agreed response time

For critical applications, customized SLAs are possible with shorter response times.

For production environments where downtime results in immediate costs, we recommend at least a service contract.

| Support within 24 hours | Discount on components | Annual preventive maintenance | On-site service within 3 working days | |

|---|---|---|---|---|

| Maintenance contract | ✓ | ✓ | ✓ | |

| Service contract | ✓ | ✓ | ✓ | ✓ |

What you actually gain with a contract

✔️ Faster problem solving

In the event of a malfunction, you'll be prioritized. In many cases, issues can be resolved remotely, minimizing downtime.

✔️ Less unplanned downtime

Preventive maintenance prevents wear or contamination from leading to unexpected failures.

✔️ Lower maintenance costs

With a contract you benefit from a discount on parts and consumables.

✔️ Predictability in planning

Maintenance is planned, not forced by downtime. This provides peace of mind in your production process.

What is included in preventive maintenance?

During the annual maintenance, our service technicians check and optimize, among other things:

- moving parts and guides (cleaning & lubrication)

- optical path (cleaning and adjusting mirrors and lenses)

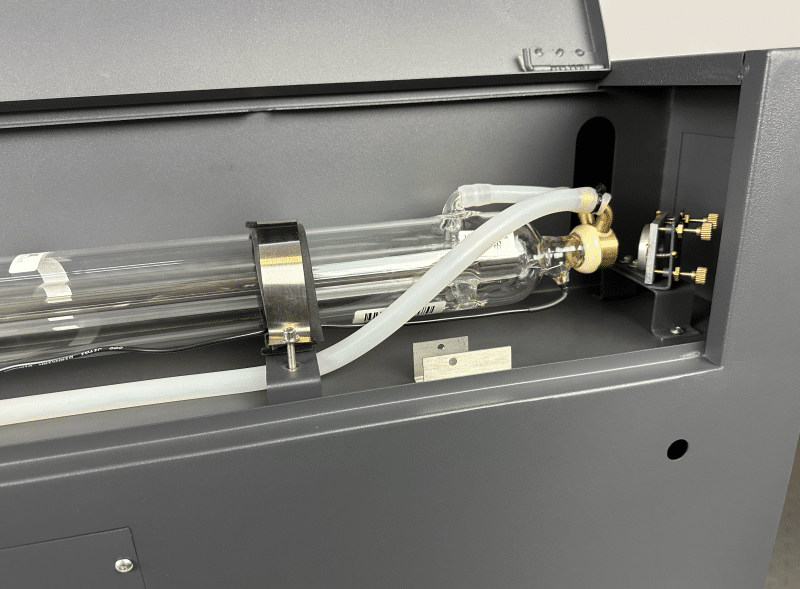

- laser tube and water cooling

- wiring and connections

- general cleaning of the machine

- test cutting and engraving

Defective parts can be replaced immediately after consultation.

Maintenance is planned, not forced by downtime. This provides peace of mind in your production process.

Discount on parts

With a maintenance contract you will receive:

- 25% discount on common parts (such as mirrors, lenses, accessories)

- 10% discount on laser tubes

This structurally reduces the total cost of ownership of your laser system.

On-site service

If a problem cannot be solved remotely, MetaQuip will come to your location.

Standard delivery within 3 business days. For production-critical environments, faster response times are possible based on customized agreements.

Which contract suits your situation?

The right choice depends on:

- how critical the laser system is in your production process

- the amount of use (hours per week)

- the impact of downtime on your planning

We are happy to help you choose a contract type that suits your business operations.

→ Contact MetaQuip for advice on service and maintenance contracts