Fiber laser cutter metal – Prototype series

€48.500,00 ex.VAT | €58.685,00 incl

Laser cutting of flat sheet material of 150 x 100cm, 200 x 100cm or 300 x 150cm. Laser powers from 1kW.

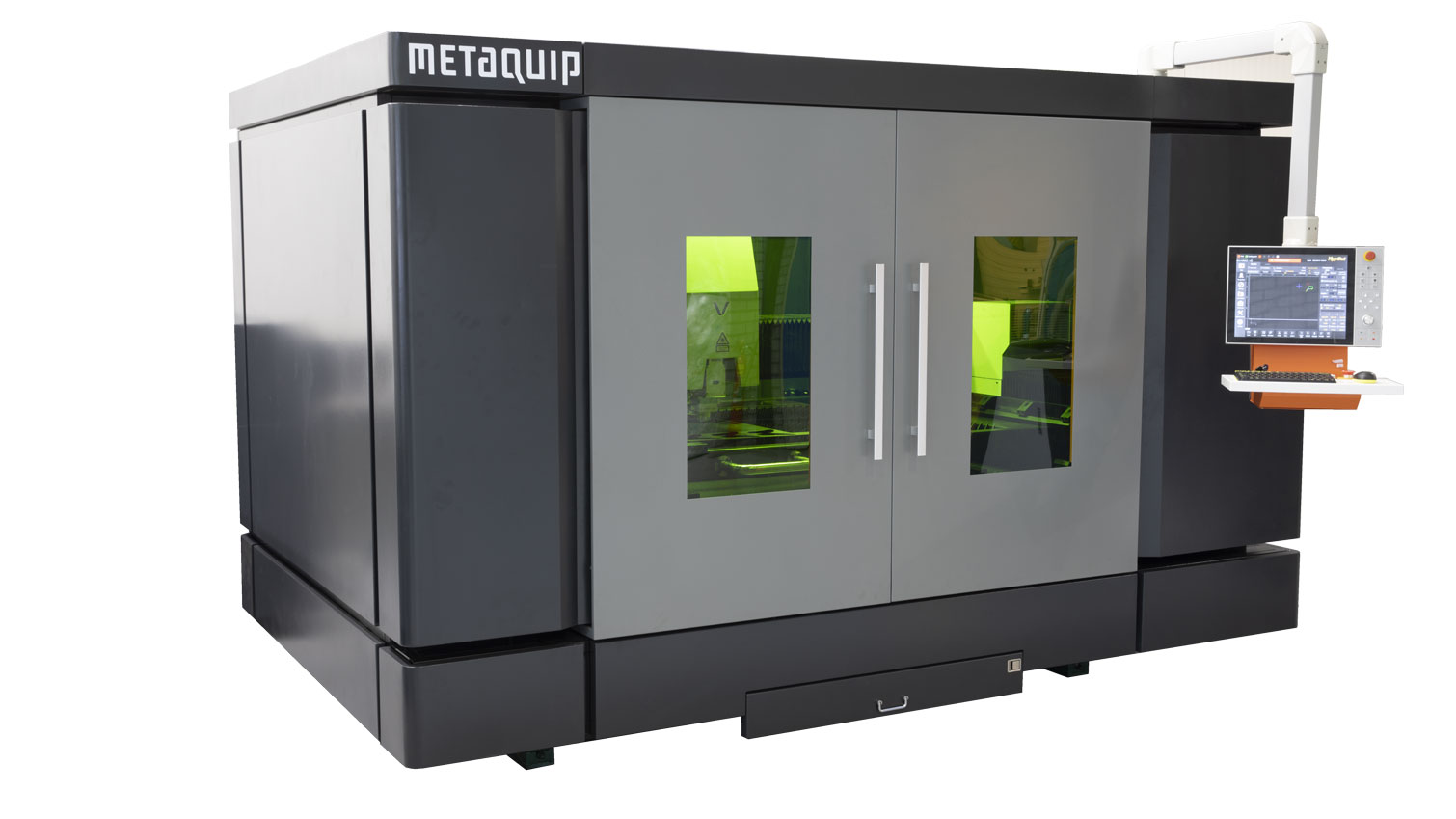

The Fiber Laser Cutter Metal from the prototype series is designed for laser cutting of thicker sheet material and solid products. The machine has a compact design, making it perfect for prototyping and small series production. The pull-out bed makes it easy to load and unload the material for the operator using a crane, eliminating the need for heavy lifting. The strong frame and rack-and-pinion servo drive deliver a combination of high accuracy and fast cutting speeds. You can laser cut a large number of metals such as carbon steel, stainless steel and brass sheet with this machine. We supply this machine in a number of workbed sizes.

Most important features

- Laser cutting: carbon steel, stainless steel, titanium, galvanized steel, brass plate, etc. Without finishing.

- Laser power: 1kW, 2kW, 3kW, 4kW, 6kW. Standard Raycus, other sources optional.

- Work surface: 1500 x 1000mm, 2000 x 1000mm or 3000 x 1500mm

- Ergonomic design - easy manual or machine loading and unloading of (heavy) sheet material.

- Minimum maintenance. No mirrors, no adjustment of the optical path.

- Easy to use. Comes standard with fully automatic focus setting.

- Software: Integrated computer with Hypcut laser software.

- Basic set of laser head service parts - Supplied complete, immediately suitable for cutting multiple metals.

- Safety: Laser class 3R - safe in all situations without extra protection.

- Certification: CE - complies with all machine guidelines.

Please note that the price shown is a starting price based on the FC1510, 1.5kW model!

Contact MetaQuip for delivery, installation and training options.

Out of stock

Description

Materials | CE & laser safety | Service & Support | Specifications | Delivery, installation & training | Guarantee

Effortless laser cutting of metals!

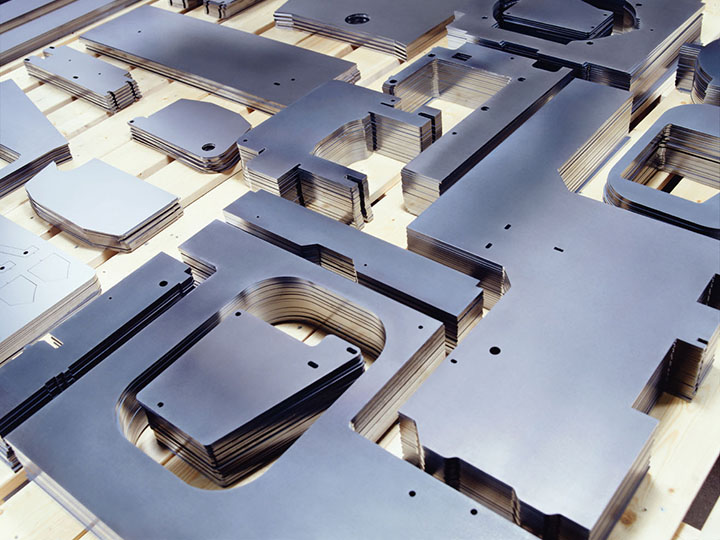

The Fiber Laser Metal Cutter from the prototype series cuts through a large number of metals at high speed and with extreme precision without further post-processing. Also suitable for thicker metal plates! This metal laser works with a direct fiber source, which ensures high reliability and limited maintenance.

Workbed dimensions

- FC1510 – work bed 1500 x 1000mm

- FC2010 – work bed 2000 x 1000mm

- FC3015 – work bed 3000 x 1500mm

Metal laser suitable for laser cutting of thick sheet material

The Fiber Laser Cutter Metal from the prototype series is designed for laser cutting of thicker sheet material. This machine is supplied with laser sources from 1kW up to 10kW to effortlessly cut even the thickest metal plates. This is MetaQuip's smallest metal laser production machine. For a larger work bed and/or interchangeable beds, see also MetaQuip FC3015 and the MetaQuip FC4020.

Rapid and flexible prototyping and production

With the MetaQuip Fiber Laser Cutter Metal from the prototype series you can quickly laser cut metal parts yourself. This is ideal for fast and flexible prototyping or small-scale production series. Converting to a different metal type, thickness or design is quick and easy. This machine can also be used for production applications. Compared to the smaller fiber laser metal cutters such as the MetaQuip FC6060 and MetaQuip FC1390, the machine is heavier, making it also suitable for heavier sheet material that can be cut at a higher speed.

High accuracy and reproducibility

The Fiber Laser Cutter Metal from the prototype series is based on the same frame, guides and drives that are also used in the large high-end steel cutters, resulting in a laser machine that combines high cutting speed with high accuracy and reproducibility. This is achieved by the extremely stiff and heavy frame of the machine. Even at high speeds, the results remain reproducible because the machine uses high-quality rack and pinion transmissions with heavy linear Hiwin guides.

Fiber Laser Cutter For Metal With High Quality Laser Source

Raycus or IPG laser source

The Fiber Laser Cutter Metal from the prototype series uses high-quality fiber laser sources from the brands Raycus and IPG. The machine is supplied with Raycus as standard, but IPG or other brands are optional. The laser head is from the Raytools brand, for which the settings can be adjusted entirely from the software.

Local service

All parts for these laser heads are in stock and where necessary the MetaQuip technicians can fully service the laser head on location, so that any downtime is kept to a minimum.

Smart crash detection

The Raytools laser head has built-in crash detection should the head hit an object, such as a cut part. After removing the object, the cutting process can be resumed.

Fully automatic autofocus sensor

MetaQuip supplies the laser head with autofocus and height tracking as standard. Particularly when laser cutting somewhat thicker plate material, this saves time because otherwise the focus height has to be adjusted again after each change of material or thickness. The automatic focus setting but setting simple, fast and less prone to error.

Height sensor

The Fiber Laser Cutter Metal from the prototype series is equipped with a fully automatic height sensor. This ensures that the laser head always follows the metal perfectly, even if the material is not completely flat. This guarantees a perfect cutting result. The height sensor samples the height 1000x per second and adjusts the height with a static accuracy of 10 micrometers (50um dynamic response accuracy) within a range of 0-25mm.

Ergonomic design

Sliding doors

The Fiber Laser Cutter Metal from the prototype series is designed for maximum user-friendliness. The two sliding doors ensure that the workspace is fully and easily accessible, without further obstacles.

Touchscreen control console

The control console consists of a complete touchscreen. This means that settings and adjustments can be made quickly. In addition, it is also possible to operate the machine with a mouse and keyboard.

The control console is flexibly attached to the machine. This gives you plenty of space during loading and unloading and also a full view when setting up the machine. Due to the applied touch screen and control buttons, the operator has all functions directly under hand / finger reach.

Extendable work bed

The Fiber Laser Cutter Metal from the prototype series have an extendable work bed. During loading and unloading of the sheet material, the workbed is completely slid out of the machine. This makes it very easy to place thicker and heavier sheet material in particular. This can be done manually or mechanically. Because the workbed protrudes from the machine, this makes placement quick and easy, without damaging the workpiece or the machine.

Machine Operation

This metal cutter is controlled and operated by Hypcut. This is the professional, touchscreen variant of Cypcut laser software. This software is easy to use and it is quick for the operator to learn how to work safely with the MetaQuip fiber laser metal laser cutters. The service of the metal laser is done entirely from the touchscreen control unit. All peripheral equipment is operated from the control unit and malfunctions mentioned in the software / cutting are blocked if this could lead to damage. If the filter unit is not active, the process will stop to prevent vapors from building up in the machine. By checking the peripheral equipment, damage can be prevented and the user has from the control unit full insight into the process. The machine is supplied with an industrial remote control as standard. This gives the user direct access to most remote functions.

Standard features on the Fiber Laser Cutter Metal – Prototype series

Air exhaust detection

The gases and vapors released from laser cutting metal can be poisonous. That is why good air extraction is essential. The moment the air extraction does not work, this is automatically detected by the security system and the machine controller automatically switches off the laser source.

Smart crash detection

Objects that are cut free can sometimes tilt upwards, creating the risk of the laser head bumping into it. The built-in smart crash detection in the laser head prevents this from happening. The laser head moves to a safe position and the machine alerts the operator so that he can remove the object and continue the laser job safely.

Water cooling for the laser head

The laser head of a fiber laser machine must be properly cooled. A high-quality water cooler with 2 separate cooling circuits is supplied as standard. As a result, the laser source and laser head with the lenses are kept separately and very accurately at the perfect temperature. Any warnings are shown on the operator's display and in the event of an alarm, the laser is immediately turned off to prevent damage.

Gas security

The gas protection prevents you from cutting without gas. If the bottle is empty, the gas pressure drops or you have simply selected the wrong gas, the machine will not start or stop laser cutting and warn you.

Automatic edge detection

The built-in height controller can automatically search the edges of the sheet material. The software can then automatically compensate so that objects are always cut within the sheet material.

Solid state laser source

MetaQuip supplies these machines with a solid state as standard Raycus fiber laser source. Raycus sources are very stable and have a service life of at least 80000 hours. Optionally, the machine can also be equipped with a IPG laser source. The laser source has no moving parts and is completely maintenance-free except for the laser head.

Hypcut laser software

MetaQuip supplies the fiber laser metal cutter with the Hypcut software program as standard. Hypcut works intuitively for both the beginner and the professional user and also has some advanced features such as automatic nesting functions to organize plates efficiently, extensive lead in / out options, micro joints, fly-cutting , pierce functions and extensive cutting settings. The entire laser machine can be operated via Hypcut and all warnings and error messages are received centrally here.

Ergonomic design

The machine has two horizontal sliding doors allowing maximum access to the machine. This one is provided with a light barrier for safety. If this is passed, the machine is immediately stopped, causing the safety of the operator.

The work bed is fully extendable, making it quick and easy to install heavy plate material

Remote control

Supplied with one as standard radiographic remote control. It allows you to control all main functions remotely. This works quickly and easily. The remote is magnetic and can easily be placed anywhere on the machine.

Touchscreen

The control console and laser software is fully touchscreen based. The large, clear buttons make it possible to make quick adjustments and guarantee easy operation.

Quotation, demonstration of this laser machine?

Materials and alloys

Type of metal & laser power

Different metals need a different laser power to be able to laser cut. In this reference table you will find a rough indication for carbon steel, stainless steel (SS), aluminum, titanium, galvanized steel, galvanized sheet and copper alloy. A higher laser power is required for cutting aluminum or copper.

Thickness of the metal & cutting speed

In general, cutting thicker steel plates requires more laser power. Time is needed for the material to melt completely. The cutting speed is therefore also an important parameter.

Help / Cutting gases

To laser cut metals auxiliary gases such as oxygen and nitrogen are needed. These are set per material type and thickness. MetaQuip itself does not supply auxiliary gases, but can advise you what the options are for your use.

Air Extraction and filtering

The metal fumes that are released during the laser cutting of metal are harmful to health. A good air extraction and filter installation is therefore necessary. MetaQuip can advise you and provide you with a suitable solution. We only work with BOFA air filters. BOFA filters achieve a higher negative pressure at lower flow rates, so that they can remove heavy particles from the machine better. Have BOFA filter through their patented design a much longer filter duration. A BOFA filter guarantees you of one good service over the years, one much lower consumption of filters, making a BOFA filter significantly cheaper to use over the competitors in the filter market.

For light use we recommend and supply the BOFA AD2000iQ with Spark arrestor. The AD2000iQ is an industrial air filter that ensures that the air is cleaned of toxic fumes and particles.

The BOFA Sparkarrestor ensures that any glowing metal parts are collected, which also extends the life of the AD2000 unit's pre-filter and reduces the risk of fire. BOFA air filters are these filters equipped with remote start / stop and feedback to the laser so that laser can only be performed if the filter is working correctly.

For more intensive use and larger machines, we also supply the BOFA AD4000iQ. MetaQuip can advise you on this.

Machine guidelines, CE certification & laser safety

For MetaQuip, laser safety is paramount as they can cause permanent damage to eyes and skin without the user realizing it. This Fiber Laser Cutter Metal from the prototype series is a closed machine. Laserkasse 3R is therefore safe for the operator at all times. The machine is CE certified and complies with the applicable machine guidelines. This machine is fully equipped with safety interlocks, has an approved emergency stop circuit and meets the applicable electrical safety requirements on all points. In addition to an approved safety circuit, MetaQuip only uses European security windows with certificate. All machines at MetaQuip are inspected on several aspects by externally accredited inspection companies (such as: Laprocon) checked in the Netherlands.

Designed by MetaQuip. Made in China.

MetaQuip designs its own machines in the Netherlands, which are produced specifically for MetaQuip at our selected Chinese partners. With the Fiber Laser Cutter Metal from the prototype series, MetaQuip has paid particular attention to making this machine suitable for quick and flexible use for prototyping and smaller series production. An ergonomic laser machine that is safe and pleasant to work with. By having our own employees on site, MetaQuip can offer the quality and safety of a European design at competitive prices. Our own technicians install the machine and provide you with training in its use, and long after the warranty period you can use our service network for your questions, parts and maintenance.

Service & Support

MetaQuip offers extensive technical support in making the right machine choice, finding out or optimizing settings for your specific material or application. MetaQuip offers various service options and contracts depending on your specific wishes and requirements.

Support and training

All machines are always unpacked at MetaQuip, checked and, where necessary, adjusted to customer specifications. So no surprises during the installation at your location. To be able to start immediately, MetaQuip has been own training courses. We guide you on the basis of the software through the various options and steps necessary to be able to cut yourself. MetaQuip can after completing the training certificate however issue the support does not end when completing the training. MetaQuip has its own support website where more support and information is offered. If questions are still not answered, you as a customer can at any time ask our technicians on our support website.

Service contracts

MetaQuip provides various options for service contracts and SLAs with different conditions, response times and agreements about availability of spare parts.

Completely delivered

- MetaQuip-FC1510/FC2010/FC3015 fiber laser cutter machine

- Integrated control with Hypcut laser software

- Radio remote control

- Industrial dual zone water cooler

- Basic set of laser head service parts

- Product & software manual (NL and EN)

Want to get a quote, demonstration or your own material?

View the Production Fiber Laser Cutter Metal in our showroom

Technical specifications

- Laser Type: Raycus laser source, IPG or other options on request.

- Laser wavelength: 1060nm

- Laser Power: 1kW, 2kW, 3kW, 4kW, 6kW (higher powers on request)

- Workbed size: 1500 x 1000mm, 2000 x 1000mm or 3000 x 1500mm

- Cutting speed: 0-30 m / min (depending on material and thickness)

- XYZ orientation precision: <+/- 0.05mm / m

- XYZ repeat precision: <+/- 0.03mm / m

- Minimum line width: <0.15mm

- Maximum travel speed: 120m / min

- Maximum load working table: 500kg

- Cooling: water cooling

- Working environment: 0-35 ° C

- Voltage requirements: 380VAC 3 phases, 50 or 60Hz, 16 / 32A (depending on laser power)

- Dimensions (L x W x H) FC1510: 350 x 250 x 240 cm (depending on the version)

- Weight: 3500/4000 kg (depending on version)

- Closed machine for maximum laser safety

- Control Software: Hypcut with CAD

- Autofocus: also tracks uneven material with an accuracy of 10 micrometers

- Door: certified (green) laser safety glass (inspection report available)

- E-chain®: yes

- Red pointer: placeholder

- Integrated computer with Touchscreen laser software

- Dutch or English product & software manual

Delivery, installation & training

Inquire about the current stock. If the machine is not in stock, the delivery time is between 11-13 weeks. This machine can be picked up or delivered at a flat rate, installed on site and you will receive basic training on how to operate the machine.

To prepare for installation, find one here installation instructions for the fiber laser metal cutter.

Guarantee

2-year guarantee on the machine, 50-100,000 hours on the laser source (depending on the brand chosen and the conditions under which the machine is used).

Want to get a quote, demonstration or your own material?

More information